Powering the Future with Precision Stainless Steel Tubes

Reliable Tubing Solutions for Energy, Nuclear, and Power Applications

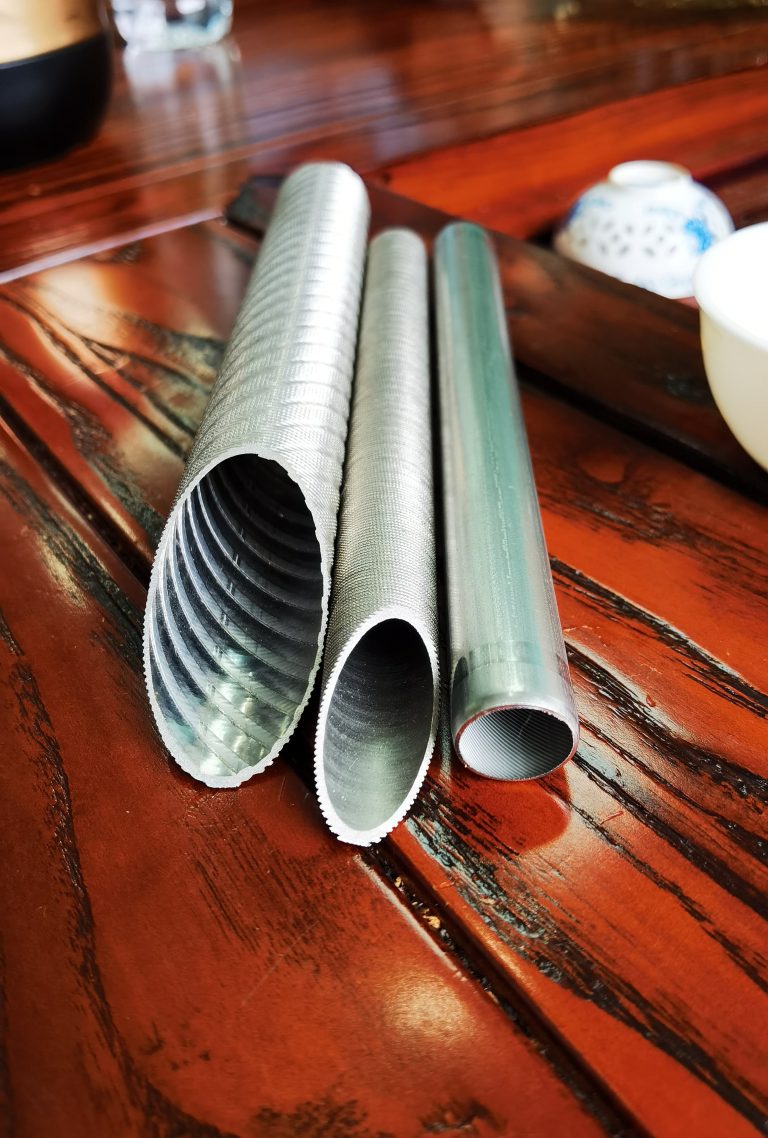

The energy and power generation industry demands robust, high-performance stainless steel tubing that can withstand extreme temperatures, high pressure, and corrosive environments. TeCarve provides precision-engineered seamless and welded tubes for boilers, superheaters, economizers, steam lines, and nuclear plant systems. Our tubes offer exceptional creep resistance, long-term strength, and metallurgical integrity, meeting global standards and inspection criteria for critical infrastructure.

Related Products

Discover more stainless steel tube and pipe options that complement your selection. Our linked products help you find the right material, shape, and specification for every industrial need. Whether you’re seeking seamless precision, welded strength, or specialized forms — we’ve got you covered.

High Temperature Resistance

Withstands thermal cycling and extreme environments

Pressure Durability

Maintains strength under sustained internal pressure

Corrosion Resistance

Excellent performance in aggressive media and condensate

Global Standards Compliance

Manufactured to ASME, ASTM, EN, JIS, GB

Custom Engineered Sizes

Tailored tube dimensions for system efficiency

Long Service Life

Reliable performance in continuous-operation environments

Applications

TeCarve’s stainless steel tubes are ideal for various energy applications, including fossil fuel power plants, nuclear power stations, waste heat recovery systems, and renewable energy systems like geothermal and biomass. Our solutions offer reliable thermal exchange, pressure handling, and resistance to oxidation and scaling.

Grades: 304, 304L, 321, 316, 347H

OD Range: 12mm – 101.6mm

Wall Thickness: 1mm – 8mm

Common Sizes: 25.4 × 2.11mm, 38.1 × 3.18mm

Finish: Annealed, Pickled, Polished

Remarks: Designed for high pressure and high temperature steam delivery

Grades: 304L, 316L, Duplex 2205

OD Range: 16mm – 63.5mm

Wall Thickness: 0.7mm – 3mm

Common Sizes: 19.05 × 1.65mm, 25.4 × 2mm

Finish: Annealed, Fin-Rolled, Polished

Remarks: Optimized for heat recovery with extended surface area

Grades: 316L, 321, TP347, Incoloy 800H (by special order)

OD Range: 12.7mm – 25.4mm

Wall Thickness: 0.8mm – 2.5mm

Common Sizes: 19.05 × 1.24mm, 22mm × 1.65mm

Finish: Bright Annealed, Passivated

Remarks: Strictly controlled for radiation-resilient material properties

Grades: 321H, 316H, 347H, TP310S

OD Range: 20mm – 80mm

Wall Thickness: 3mm – 12mm

Common Sizes: 38.1 × 4.57mm, 50.8 × 6.35mm

Finish: Annealed, Shot-Blasted, Pickled

Remarks: Designed for elevated temperature strength and pressure retention

Grades: 304, 316Ti, Duplex SS

OD Range: 12mm – 50.8mm

Wall Thickness: 0.6mm – 2mm

Common Sizes: 19.05 × 1mm, 25.4 × 1.5mm

Finish: Polished, Etched, Custom

Remarks: High thermal efficiency in corrosive and mineral-heavy environments

Contact TeCarve