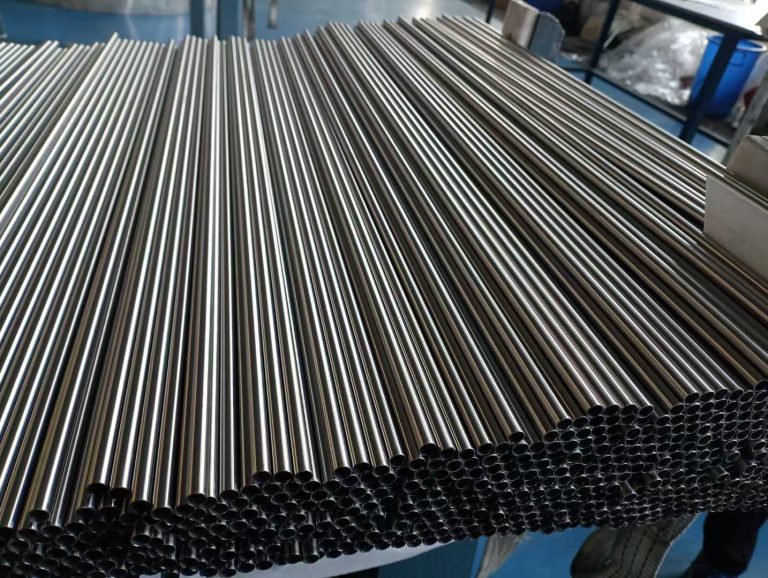

High-Performance Stainless Steel Tubes for Oil & Gas Applications

Engineered for extreme conditions — corrosion-resistant, pressure-tested tubing for upstream, midstream, and downstream reliability.

The oil & gas industry demands materials that perform under extreme temperatures, pressures, and corrosive environments. TeCarve’s stainless steel tubing solutions are precision-engineered to meet these requirements, ensuring integrity, safety, and durability from offshore drilling platforms to refineries and LNG terminals.

Our product range includes seamless and welded tubes specifically tailored for oil exploration, gas gathering systems, hydraulic control lines, injection wells, and high-temperature steam applications. With superior resistance to chloride stress corrosion, sour service, and aggressive chemicals, our tubes are trusted globally in upstream, midstream, and downstream projects.

Related Products

Discover more stainless steel tube and pipe options that complement your selection. Our linked products help you find the right material, shape, and specification for every industrial need. Whether you’re seeking seamless precision, welded strength, or specialized forms — we’ve got you covered.

Excellent Corrosion Resistance

Withstands chloride, H2S, and CO₂ environments

Pressure Integrity

Rated for high-pressure hydraulic and process lines

Extreme Temperature Endurance

Performs reliably in high-heat and cryogenic zones

NACE Compliance

Meets MR0175 / ISO 15156 sour service standards

Custom Cut-to-Length

Available in spooled coils or straight lengths up to 18m

Precision Engineering

Tight tolerances, clean ID/OD, orbital weld-ready

Applications

TeCarve’s stainless steel tubing is widely applied in critical oil & gas systems such as hydraulic control lines, instrumentation tubing, chemical injection, downhole tools, gas lift, and steam-assisted gravity drainage (SAGD). Our tubing meets NORSOK, ASTM, EN, and API standards, ensuring global compatibility and safety compliance.

Grades: 316L, 825, 625

OD Range: 1/8" – 3/8" (3.18mm – 9.53mm)

Wall Thickness: 0.71mm – 1.65mm

Common Size: 6.35 × 1.0mm, 9.53 × 1.65mm

Finish: Bright Annealed

Remarks: Supplied in continuous coil up to 6,000 meters

Grades: 316L, 904L, Alloy 825

OD Range: 6mm – 19.05mm

Wall Thickness: 0.89mm – 2.11mm

Common Size: 12.7 × 1.24mm

Finish: Pickled or Polished

Remarks: Optional PVC jacketing

Grades: 316Ti, Duplex 2205, 2507

OD Range: 12mm – 25mm

Wall Thickness: 2mm – 5mm

Common Size: 19.05 × 2.77mm

Finish: Mill Finish

Remarks: NACE MR0175 compliant

Grades: 316/316L, 321

OD Range: 1/4" – 1" (6.35mm – 25.4mm)

Wall Thickness: 0.89mm – 2.11mm

Common Size: 12.7 × 1.24mm

Finish: Bright Annealed

Remarks: Compatible with Swagelok® fittings

Grades: 316L, 347H, 625

OD Range: 12.7mm – 38.1mm

Wall Thickness: 1.65mm – 4mm

Common Size: 25.4 × 2.11mm

Finish: Descaled or Shot Blasted

Remarks: High-temp service > 600°C

Grades: 316L, 825

OD Range: 1.6mm – 6mm

Wall Thickness: 0.2mm – 1mm

Common Size: 3.18 × 0.5mm

Finish: Bright Annealed

Remarks: Small-bore delivery lines

Contact TeCarve