Advanced Stainless Steel Tubing for Chemical & Petrochemical Applications

Built for corrosion resistance, pressure endurance, and long-term chemical exposure

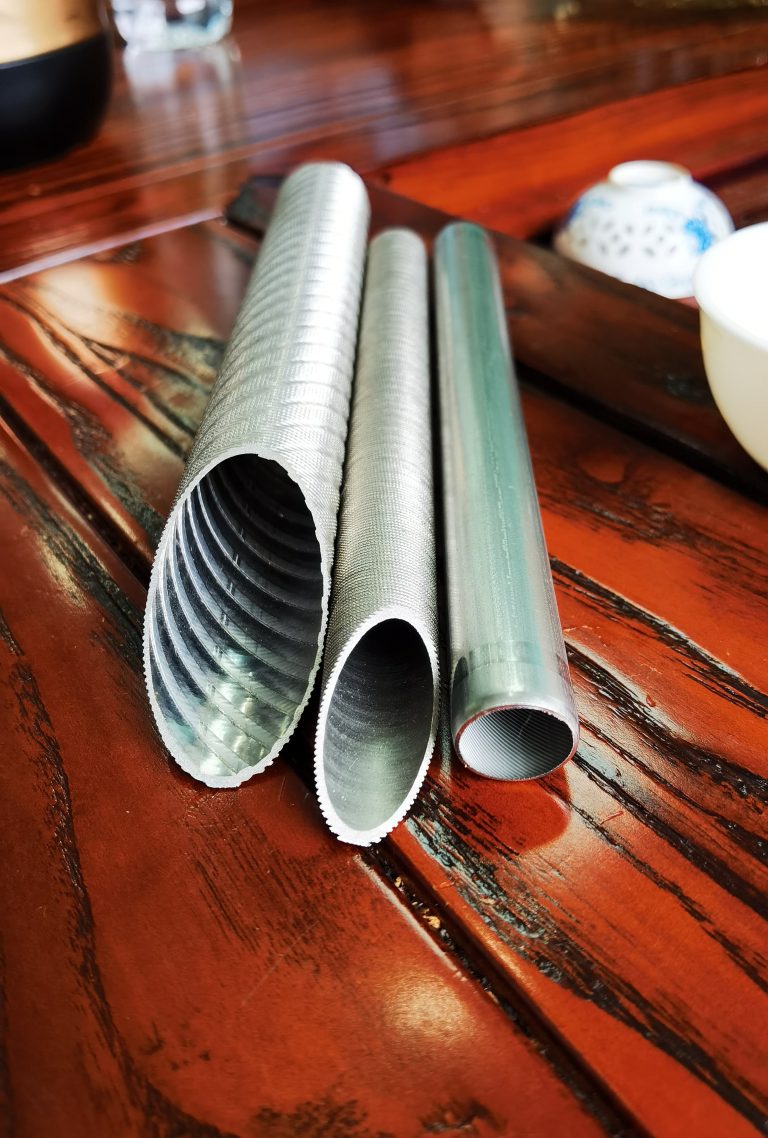

TeCarve’s stainless steel tubing solutions are widely used in the chemical and petrochemical sectors, where materials must withstand high pressure, temperature fluctuations, and aggressive corrosive substances. Our seamless and welded tubes meet strict international standards and are tailored to handle the extreme demands of fluid transport, heat exchange, and processing in reactors, pipelines, condensers, and heat exchangers.

With our proven expertise and global logistics, TeCarve supports chemical clients in building safer, more efficient, and longer-lasting infrastructure.

Related Products

Discover more stainless steel tube and pipe options that complement your selection. Our linked products help you find the right material, shape, and specification for every industrial need. Whether you’re seeking seamless precision, welded strength, or specialized forms — we’ve got you covered.

Corrosion Resistance

Performs under acidic, alkaline, and chloride-rich environments

High-Temperature Strength

Retains mechanical integrity at elevated process temperatures

Clean Internal Surface

Reduces fouling and contamination risks

Precise Dimensions

Ensures secure fittings and smooth fluid dynamics

Custom Fabrication Available

Custom Fabrication Available

Custom Fabrication Available

Fulfills ASTM, EN, JIS, and ISO specifications for chemical-grade materials

Applications

TeCarve’s stainless steel tubes are applied across reactors, condensers, process lines, scrubbers, and thermal units in chemical and petrochemical facilities. Tubes are engineered to handle aggressive fluids, thermal cycling, and pressure differentials, ensuring safety, performance, and low maintenance over long service life.

Grades: 316L, 904L, 317L, Alloy 625

OD Range: 6mm – 114mm

Wall Thickness: 0.8mm – 6mm

Common Size (mm): 19.05 × 2.11, 25.4 × 2.77, 38.1 × 3.18

Finish: Pickled / Bright Annealed

Remarks: Chloride-rich and acidic fluid compatible

Grades: 304L, 316L, 321, 317L

OD Range: 9.52mm – 25.4mm

Wall Thickness: 0.5mm – 2.5mm

Common Size (mm): 19.05 × 1.65, 25.4 × 2.11

Finish: Polished / Annealed / Fin-Enhanced

Remarks: Enhanced heat transfer and compact layouts

Grades: 316Ti, 317L, 904L

OD Range: 12mm – 60mm

Wall Thickness: 1.0mm – 4.0mm

Common Size (mm): 38.1 × 2.77, 50.8 × 3.18

Finish: Pickled / Matte

Remarks: Suitable for sulfuric acid and exhaust processing

Grades: 316L, Alloy 625, TP347H

OD Range: 6mm – 50mm

Wall Thickness: 1.5mm – 6mm

Common Size (mm): 12.7 × 2.0, 25.4 × 3.0

Finish: Bright Annealed

Remarks: For gas/liquid transport under elevated pressure

Grades: 304L, 316L

OD Range: 6mm – 25mm

Wall Thickness: 0.5mm – 1.65mm

Common Size (mm): 12.7 × 0.89, 19.05 × 1.24

Finish: Bright Annealed / Polished

Remarks: Withstands extreme low temperatures in LNG or chemical storage

Grades: 316L, 825, Alloy C276

OD Range: 3mm – 15mm

Wall Thickness: 0.5mm – 1.5mm

Common Size (mm): 6.35 × 0.89, 9.52 × 1.24

Finish: Coil Annealed

Remarks: Supplied in long lengths with low seam count

Contact TeCarve