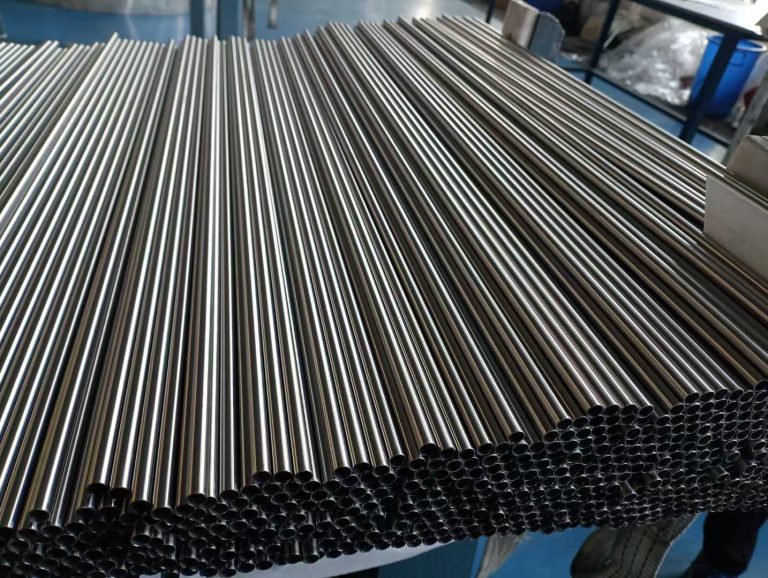

Optimized Stainless Steel Tubes for HVAC & Heat Exchange Efficiency

Delivering corrosion resistance, thermal efficiency, and durability for your critical heating and cooling systems.

TeCarve’s stainless steel tubing solutions are engineered for optimal thermal performance, corrosion resistance, and long-term reliability in HVAC and heat exchanger systems. From chilled water lines and boiler coils to industrial condensers and evaporators, our tubes deliver efficiency and durability in both residential and commercial applications.

We offer a wide range of precision-engineered seamless and welded tubes that meet international standards such as ASTM, EN, and JIS. These tubes are widely used in shell & tube heat exchangers, HVAC coils, absorption chillers, air conditioning systems, and various heat recovery units.

Key benefits include high thermal conductivity, resistance to pitting and scaling, ease of fabrication, and consistent dimensional tolerances—making TeCarve tubing a preferred choice for OEMs and HVAC contractors worldwide.

Related Products

Discover more stainless steel tube and pipe options that complement your selection. Our linked products help you find the right material, shape, and specification for every industrial need. Whether you’re seeking seamless precision, welded strength, or specialized forms — we’ve got you covered.

Excellent Corrosion Resistance

Stainless steel withstands moisture, condensate, and various chemicals — ideal for long-term use in HVAC and exchanger environments.

Superior Heat Transfer Efficiency

High thermal conductivity ensures effective heat exchange performance, improving overall system energy efficiency.

Durability & Strength

Withstands high pressure and temperature fluctuations without deformation, cracking, or material fatigue.

Hygienic and Easy to Clean

A smooth, non-porous surface resists bacterial growth, meeting standards for clean air and sanitary systems.

Low Maintenance & Long Service Life

Minimal upkeep required — stainless steel reduces system downtime and long-term operational costs.

Recyclable & Environmentally Friendly

Fully recyclable and sustainable, stainless steel supports green building and energy-efficient solutions.

Applications

Stainless steel tubes and pipes are essential components across HVAC and heat exchanger systems, offering unmatched durability, corrosion resistance, and thermal performance. Below are key application areas and their commonly used specifications

Grades: 304, 316L

OD Range: 6mm – 25.4mm

Wall Thickness: 0.5mm – 2.0mm

Common Size: 9.52mm × 0.5mm, 12.7mm × 0.6mm, 15.88mm × 0.8mm

Finish: Bright Annealed (BA), Polished (180–600 grit)

Remarks: Used for refrigerant lines and evaporator coils

Grades: 304, 316L, 904L

OD Range: 12.7mm – 38.1mm

Wall Thickness: 0.7mm – 2.11mm

Common Size: 16mm × 1.0mm, 19mm × 1.0mm, 25.4mm × 1.2mm

Finish: Annealed + Pickled, Mechanical Polishing

Remarks: Designed for thermal cycling and pressure resistance

Grades: 304, 321, 316Ti

OD Range: 10mm – 50.8mm

Wall Thickness: 1.0mm – 3.0mm

Common Size: 21.3mm × 2.0mm, 25.4mm × 2.5mm, 33.7mm × 3.0mm

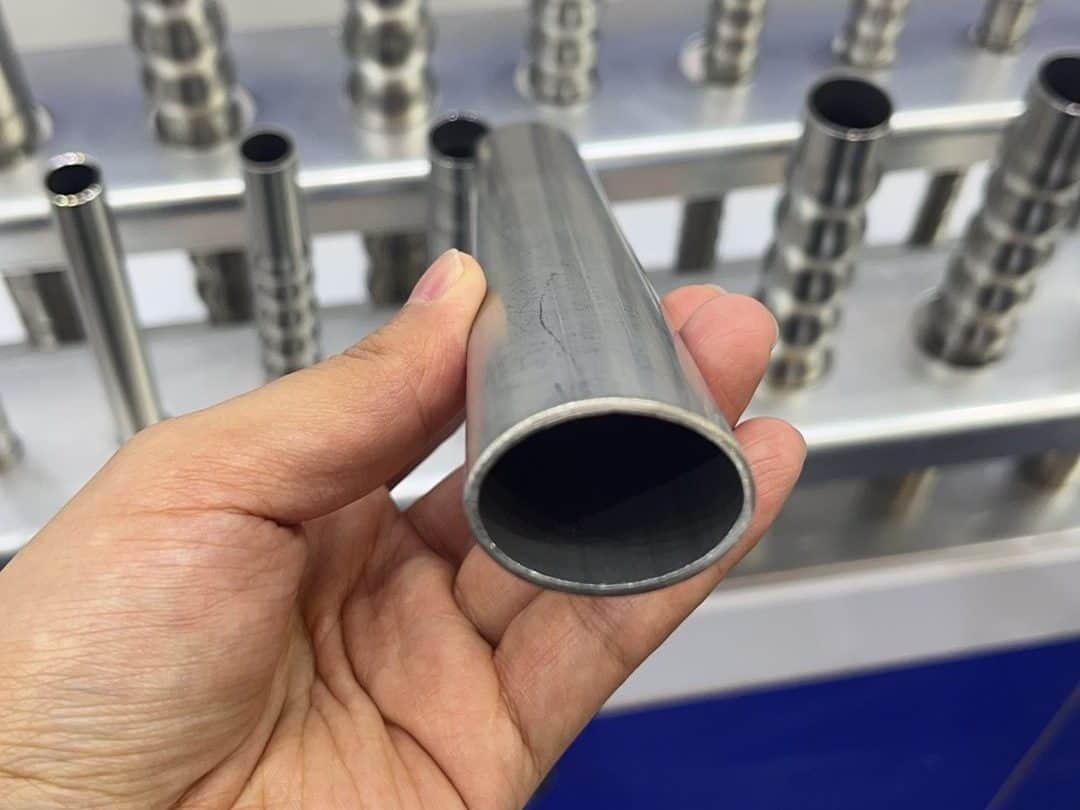

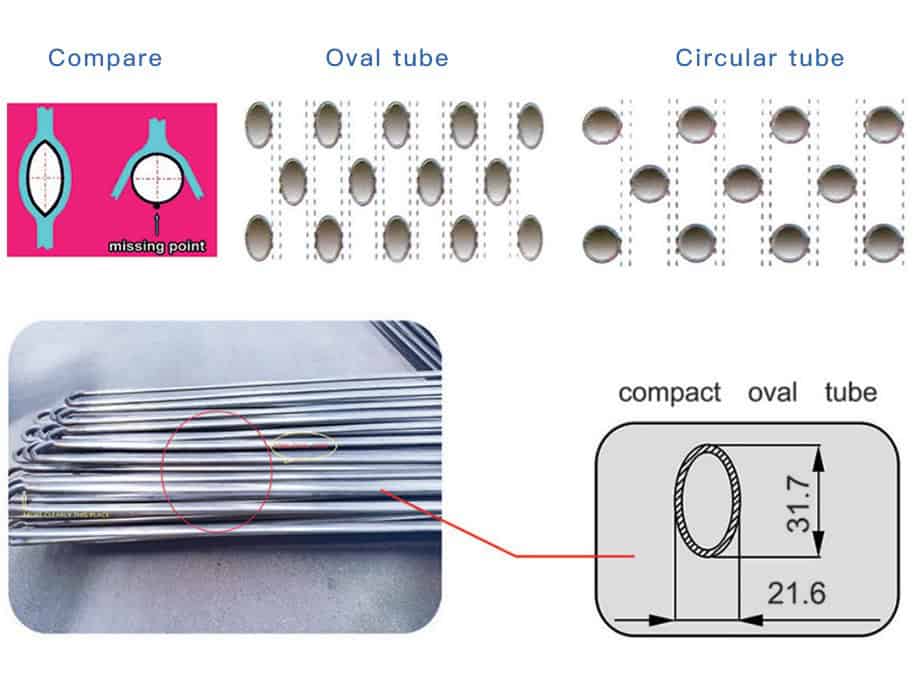

Oval Tube Size: 31.7mm x 21.6mm

Finish: Annealed, Bead Removed Inside

Remarks: Withstands high temperatures and steam environments

Grades: 304, 439 (ferritic for cost-effectiveness)

OD Range: 19mm – 100mm or custom profile

Wall Thickness: 0.6mm – 1.5mm

Common Size: 38.1mm × 0.7mm, 50.8mm × 0.9mm, 63.5mm × 1.0mm

Oval Tube Size: 31.7mm x 21.6mm

Finish: Satin, Hairline, Mirror

Remarks: Often used in visible architectural HVAC ducting

Grades: 316L, 317L

OD Range: 0.5mm – 10mm

Wall Thickness: 0.3mm – 1.0mm

Common Size: 10mm × 1.0mm, 12mm × 1.2mm, 16mm × 1.5mm

Finish: Bright Annealed

Remarks: Precision tubing for compact, high-efficiency systems

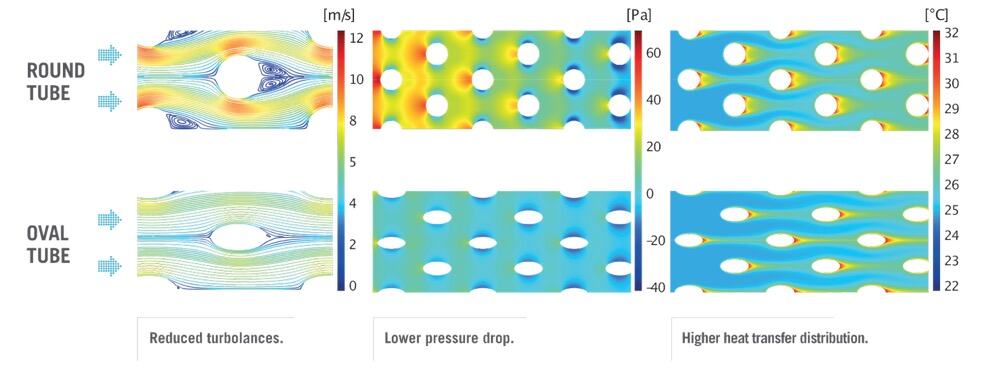

Round Tubes VS Oval Tubes

Contact TeCarve