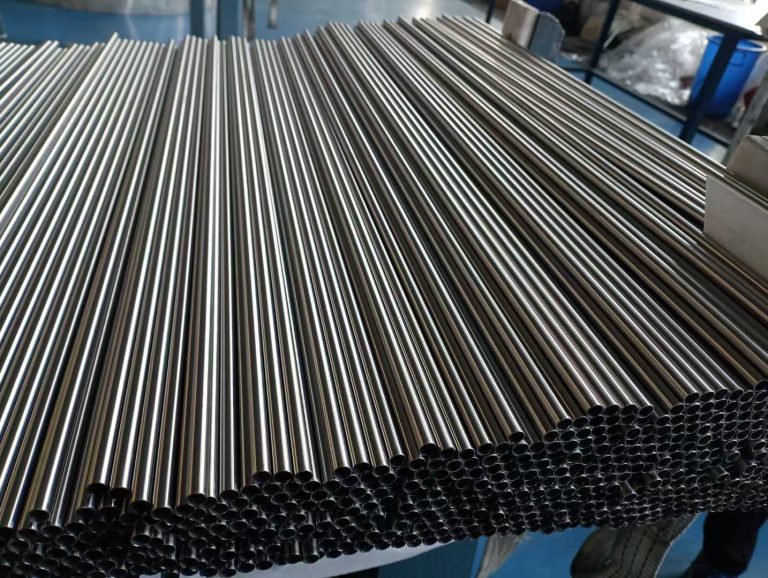

Precision Tubing for Pharmaceutical & Medical Systems

High-Purity Stainless Steel Tubes for Critical Sanitation and Biotech Performance

TeCarve provides pharmaceutical & medical grade stainless steel tubes with exceptional cleanliness, corrosion resistance, and compliance with global hygiene standards. Suitable for cleanroom, fluid delivery, and biotech processing systems.

TeCarve delivers high-purity stainless steel tube solutions specifically designed for the pharmaceutical, biotech, and medical sectors. These industries demand flawless internal surfaces, ultra-low roughness, and strict dimensional control to ensure fluid cleanliness and system sterility.

We supply both seamless and welded tubing that meets global pharmaceutical-grade standards, supporting applications from sterile liquid transport to medical device frameworks. All products are produced in clean environments, fully traceable, and subject to rigorous quality validation.

Related Products

Discover more stainless steel tube and pipe options that complement your selection. Our linked products help you find the right material, shape, and specification for every industrial need. Whether you’re seeking seamless precision, welded strength, or specialized forms — we’ve got you covered.

Ultra-Clean Internal Surface

Electropolished and passivated for particle-free flow

Biocompatible Materials

304L, 316L, and 317L grades certified for clean media

Smooth Weld Beads

Orbital or laser welded for seamless interior transitions

Excellent Corrosion Resistance

Resistant to acids, disinfectants, and bio-cleaning agents

Full Traceability & Certification

Each batch accompanied with MTC, surface, and cleanliness reports

Hygienic Design Options

Custom lengths, flange prep, or pre-fabricated bends available

Applications

TeCarve’s stainless steel tubing supports sterile fluid transfer, cleanroom utility piping, drug production systems, and biotech purification setups. Our solutions enable safe, compliant, and efficient operation across FDA, GMP, and EU standards.

Grades: 316L, 317L

OD Range: 6mm – 101.6mm

Wall Thickness: 0.5mm – 2mm

Common Sizes in mm: 19.05mm × 1.5mm, 25.4mm × 1.5mm, 38.1mm × 1.5mm

Finish: Electro-polished, passivated

Remarks: 0.4µm Ra inner roughness, FDA & GMP compliant

Grades: 304L, 316L

OD Range: 1mm – 12mm

Wall Thickness: 0.2mm – 1mm

Common Sizes in mm: 6mm × 0.5mm, 8mm × 1mm

Finish: BA, EP

Remarks: Oil-free, inner cleanliness tested per ASTM G93

Grades: 316L, 317L

OD Range: 10mm – 38mm

Wall Thickness: 0.6mm – 1.5mm

Common Sizes in mm: 25.4mm × 1.5mm, 38.1mm × 1.2mm

Finish: EP, polished

Remarks: Low endotoxin level, suitable for CIP/SIP cycles

Grades: 304, 316

OD Range: 2mm – 10mm

Wall Thickness: 0.2mm – 0.8mm

Common Sizes in mm: 3mm × 0.5mm, 6mm × 0.6mm

Finish: Polished, mirror

Remarks: Suitable for bending, forming, and laser cutting

Grades: 316L

OD Range: 0.5mm – 3mm

Wall Thickness: 0.1mm – 0.3mm

Common Sizes in mm: 1.6mm × 0.2mm, 2.0mm × 0.3mm

Finish: Bright annealed

Remarks: Biocompatible and non-reactive

Grades: 304L, 316L

OD Range: 4mm – 16mm

Wall Thickness: 0.5mm – 1mm

Common Sizes in mm: 6.35mm × 0.9mm, 12.7mm × 1.0mm

Finish: Polished, pickled

Remarks: Compatible with analytical-grade fluid systems

Contact TeCarve