STAINLESS STEEL TUBING SOLUTIONS FOR WATER TREATMENT SYSTEMS

Reliable. Corrosion-Resistant. Engineered for Pure Performance.

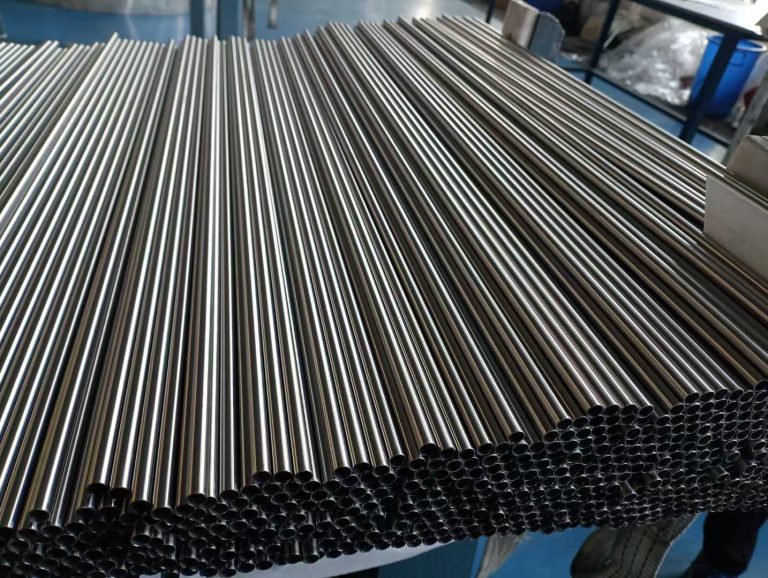

TeCarve provides stainless steel tube solutions for water purification, desalination, and industrial wastewater treatment. High corrosion resistance and hygienic standards ensure durability and safety in critical liquid-processing systems.

Water treatment applications demand durable, hygienic, and corrosion-resistant tubing systems that withstand continuous contact with aggressive agents such as chlorides, salts, and cleaning chemicals. TeCarve supplies high-quality stainless steel tubes engineered for municipal water systems, industrial wastewater treatment, RO desalination, and ultrapure water applications. Our precision manufacturing ensures tight tolerances, clean surfaces, and custom lengths, tailored to the operational demands of each water treatment system.

Related Products

Discover more stainless steel tube and pipe options that complement your selection. Our linked products help you find the right material, shape, and specification for every industrial need. Whether you’re seeking seamless precision, welded strength, or specialized forms — we’ve got you covered.

Excellent Corrosion Resistance

Excellent durability in chloride and high-salinity environments

Hygienic Standards

Clean inner surface to prevent bacterial buildup and contamination

Long Service Life

Reduced maintenance in harsh fluid conditions

Custom Lengths & Sizes

Cut-to-size solutions for system integration

Smooth Flow Efficiency

Tight surface roughness control for optimized liquid flow

Global Compliance

Meets ASTM, EN, ISO, JIS, and GB water-grade standards

Applications

TeCarve stainless steel tubes are used in a wide range of water treatment systems, from municipal drinking water networks to ultrapure process water setups in electronics and pharmaceutical industries. Our products play key roles in RO (Reverse Osmosis), UF (Ultrafiltration), EDI (Electrodeionization), and filtration systems, ensuring safe, clean, and efficient fluid handling.

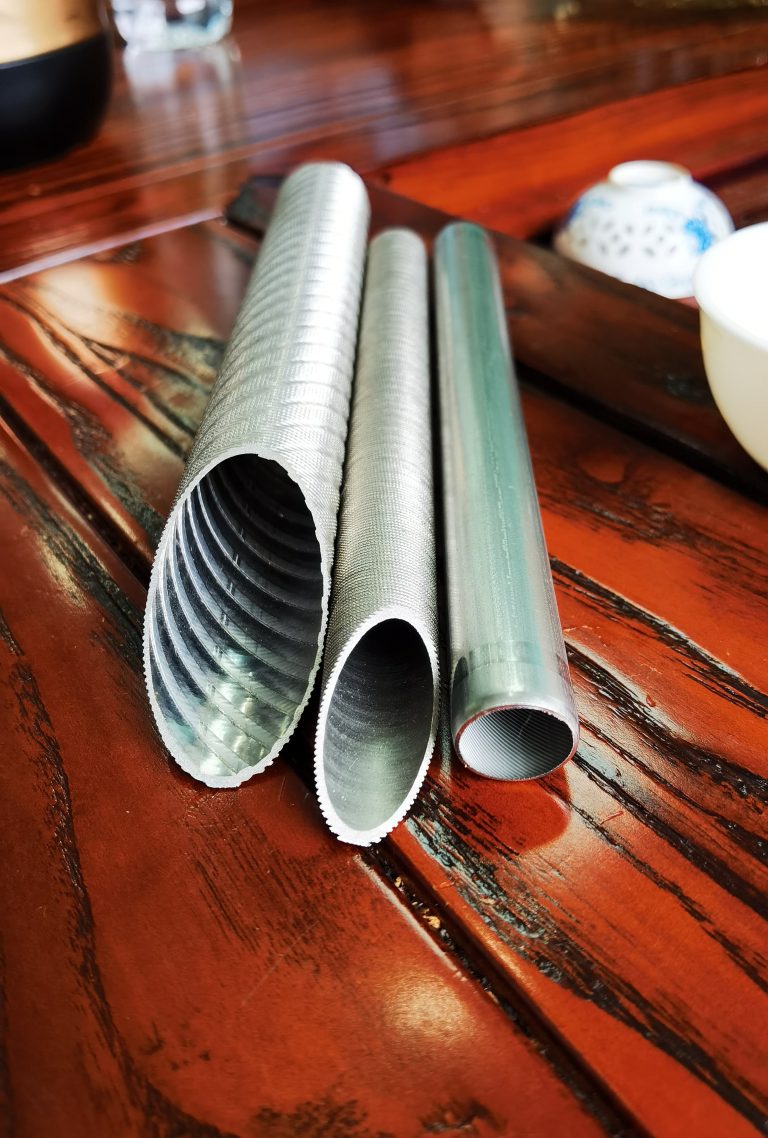

Grades: 304L, 316L, Duplex 2205

OD Range: 6mm – 60mm

Wall Thickness: 0.5mm – 3.0mm

Common Size: 19mm × 1.2mm / 25.4mm × 1.5mm

Finish: Annealed, Polished

Remarks: High chloride resistance for seawater desalination

Grades: 316L, 316Ti

OD Range: 12.7mm – 50.8mm

Wall Thickness: 1.0mm – 2.0mm

Common Size: 19.05mm × 1.5mm / 38.1mm × 1.5mm

Finish: Electro-polished

Remarks: BPE-compliant for pharma/electronics cleanrooms

Grades: 304, 316L

OD Range: 12mm – 101.6mm

Wall Thickness: 1.0mm – 4.0mm

Common Size: 38mm × 2.0mm / 50.8mm × 3.0mm

Finish: Pickled & Passivated

Remarks: Withstand chemical cleaning and abrasive fluids

Grades: 304, 316

OD Range: 20mm – 100mm (width/height)

Wall Thickness: 1.0mm – 3.0mm

Common Size: 40mm × 40mm × 2mm / 50mm × 25mm × 2mm

Finish: Brushed, Matte

Remarks: Structural support in water skids and frames

Contact TeCarve